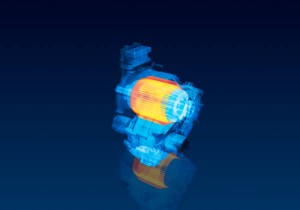

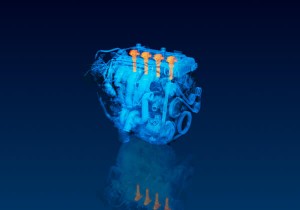

700 bar H2 tanks: smaller and lighter in partnership with Voith

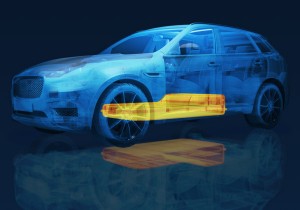

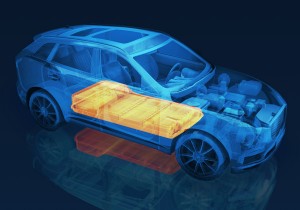

Huntsman Advanced Materials and Voith have partnered to meet the industry's demand for safe, lightweight, and high quality hydrogen composite pressure vessels. The collaboration aimed to achieve best cost-performance ratio of the pressure vessels by implementing a new mass production process using towpreg material.