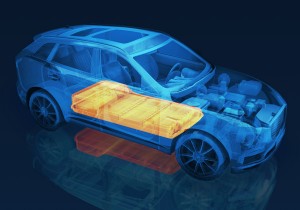

Our long-lasting, reliably-sealing solutions offer high flexibility and crack resistance, optimized thermal conductivity, excellent thermal endurance and improved chemical stability. They are ready for high-voltage applications (800 V) in the next generation of electric vehicles.

Huntsman offers a wide range of epoxy-based and polyurethane resins. All are fast-curing even at low temperatures, which improves production throughput and delivers cost savings.

Our chemists have long-standing expertise in developing advanced resins and hardeners. This enables us to stay current with ever more complex requirements in automotive electronics. Research and development activities are aimed at meeting the challenges of today and tomorrow.