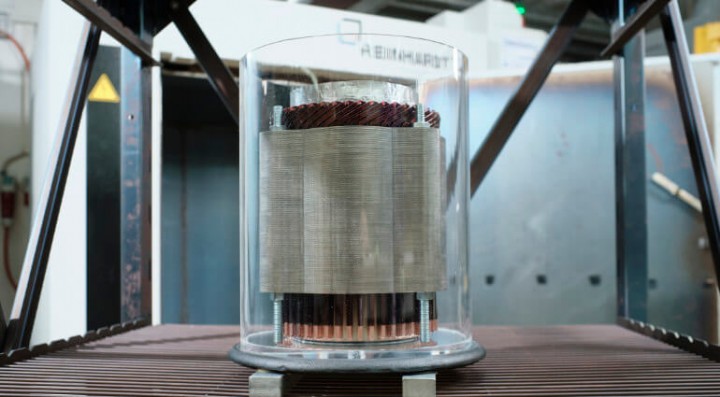

Processing

Your production processes need to combine superior efficiency with exceptional end-product performance. Huntsman’s laboratories can duplicate your processes, and offer on-site support, to help you find the best parameters (vacuum, temperature, pressure) for the most appropriate resin systems. With our processing help, you’ll need fewer trials to optimize quality and performance for each part.