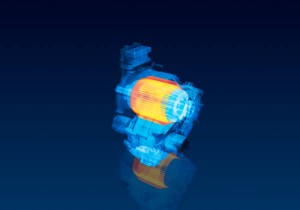

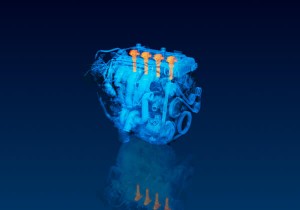

Ignition Coil

Automotive ignition coils are cast in filled epoxy resins, which penetrate voids within the winding and provide electrical insulation and heat conduction. Potting of ignition coils reduces transformer and inductor hot spots and extends component reliability and lifespan. Huntsman produces epoxy systems specially designed to insulate and protect high-voltage coil components.