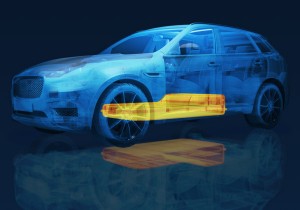

Leaf Spring

Composites' high strength-to-weight ratio, fatigue resistance and natural frequency qualities make them an excellent choice for leaf spring applications. A composite leaf spring can be up to five times more durable than a steel spring. Huntsman's composite solutions offer industry-leading performance as we work closely with customers to optimize production processes.