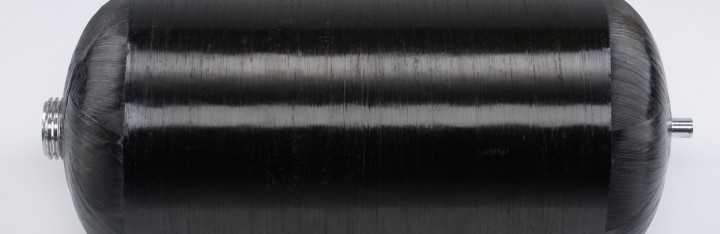

Wet Filament Winding

The Wet Filament Winding (WFW) process is used to manufacture cylindrical or hemispherical composite structures by winding fiber from a bobbin. The fiber is impregnated with resin just prior to being wound onto the mandrel. The main automotive applications are pressure vessels for CNG or hydrogen, drive shafts and other rotationally symmetrical parts.