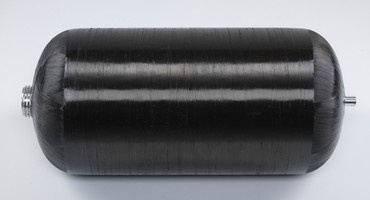

Processes for Composites

Our unique process expertise not only gives you greater confidence when developing new products with specific performance characteristics, but it also means we can support you in other key areas, such as lowering production wastes and processing times, and by improving your production line stability.