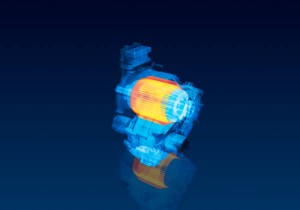

Rotor for E-Motor

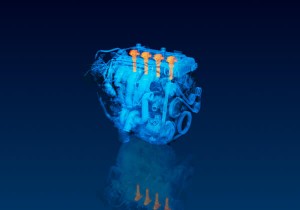

Secondary insulation materials provide several essential benefits in e-motor designs. Impregnation, particularly potting, can greatly lower operating temperature, resulting in higher power output, longer motor life and better reliability. It also helps to reduce mechanical stress, protect windings from contaminants (water, dust, chemicals), and provide an optimal insulation structure.