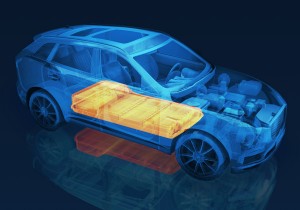

Battery Packs

The battery is the key component of any electrified vehicle, and improving battery efficiency, safety and cost are top priorities for vehicle designers. Encapsulation technology is a valuable tool to address these issues. Huntsman offers casting and impregnating resin systems for batteries, wire harnesses, connectors, sensors, switches and electronic control units.