Applications for Composites

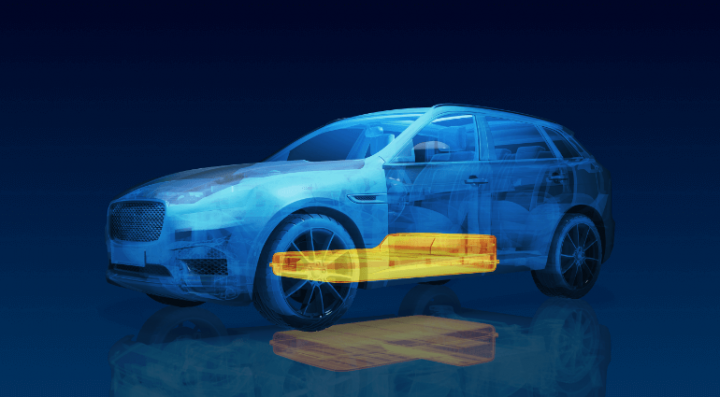

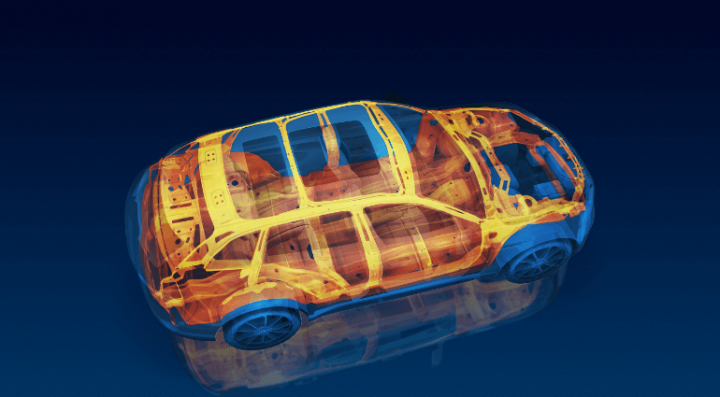

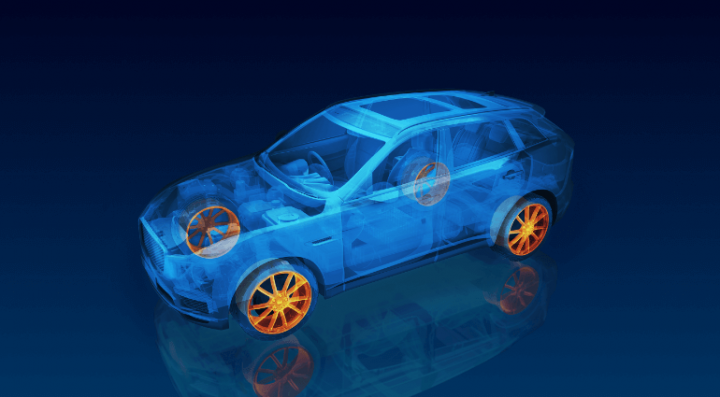

Vehicle manufacturers are constantly looking for ways to improve safety and efficiency, and integrate alternative fuels into their designs. This means they need materials that are more durable in high-use applications and that have better space-to-weight ratios. Composites are the natural solution for parts such as battery housing, pressure vessels, leaf springs, body in white and wheels.