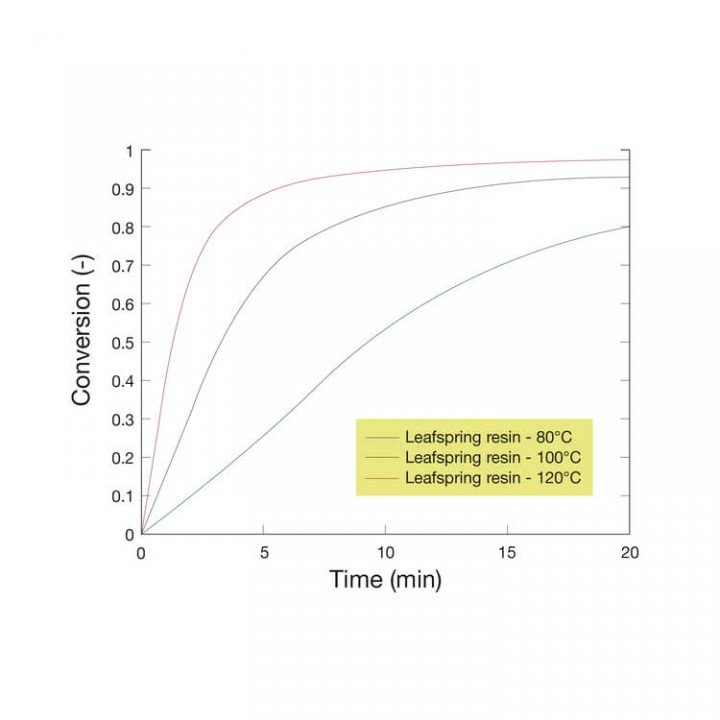

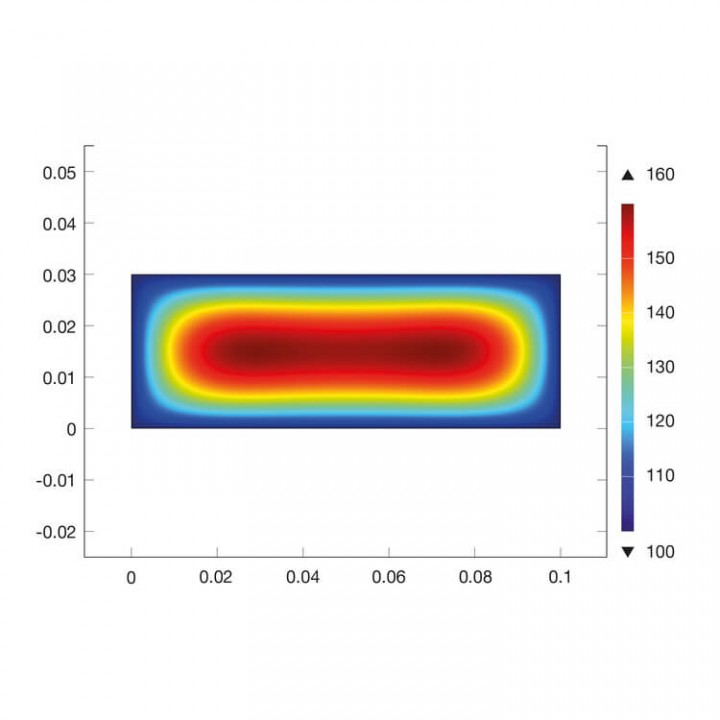

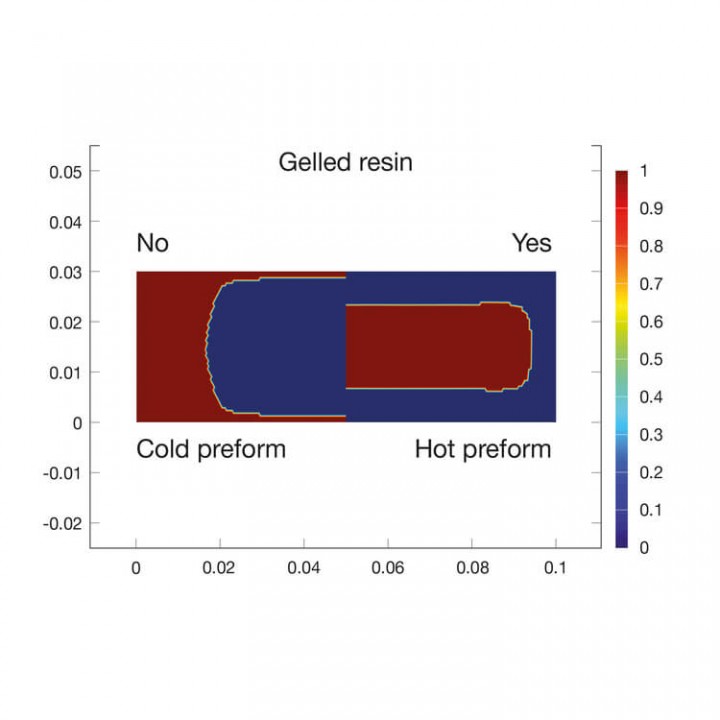

Simulation

Computer simulation of production processes is a valuable tool that can greatly shorten the development phase of a product and accelerate time to market. Simulation exercises can quickly demonstrate the limitations or the achievable characteristics for various sets of resins and processing parameters, thus reducing the number of real-world trials that must be conducted.